PROFIDRILL PDL-3D: THE BACKBONE OF YOUR CONSTRUCTION OPERATION

Whether building a skyscraper, bridge, ship, or other heavy construction project, structural steel beam drill lines are the backbone of your construction operation.

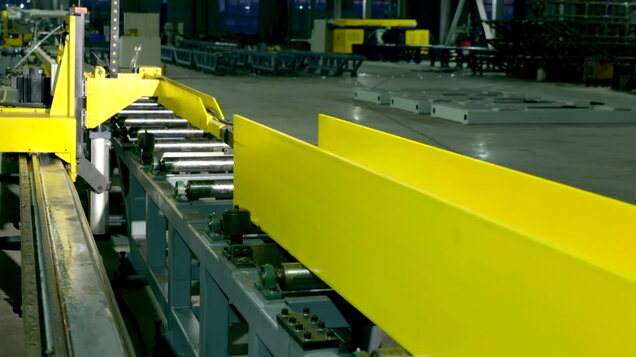

Our beam drill lines are made up of a series of connected machines that allow you to cut, drill, process, and transport structural steel beams and profiles on your construction site.

Specification | Unit | PDL-400-3D | |

Beam/Profile size (height x width) | Max. | mm | 400 x 400 |

Min. | mm | 150 x 100 | |

Profimach shows its technology in steel construction drilling lines and moves it from Europe to the World.

Our CNC drilling lines with servo motors driven are designed in Belgium and produced under OEM by a famous Asian machine tool maker to give the customer a price advance.

Our Profidrill PDL-3D-PRO series of cnc drilling lines, provide high quality solutions in manufacturing of steel construction, bridge construction, shipyards and various fields of construction sector. Profidrill PDL-3D-PRO series have the drilling capacity of H, I, and U profiles or angles with 10-35 mm standard diameters or optional more.

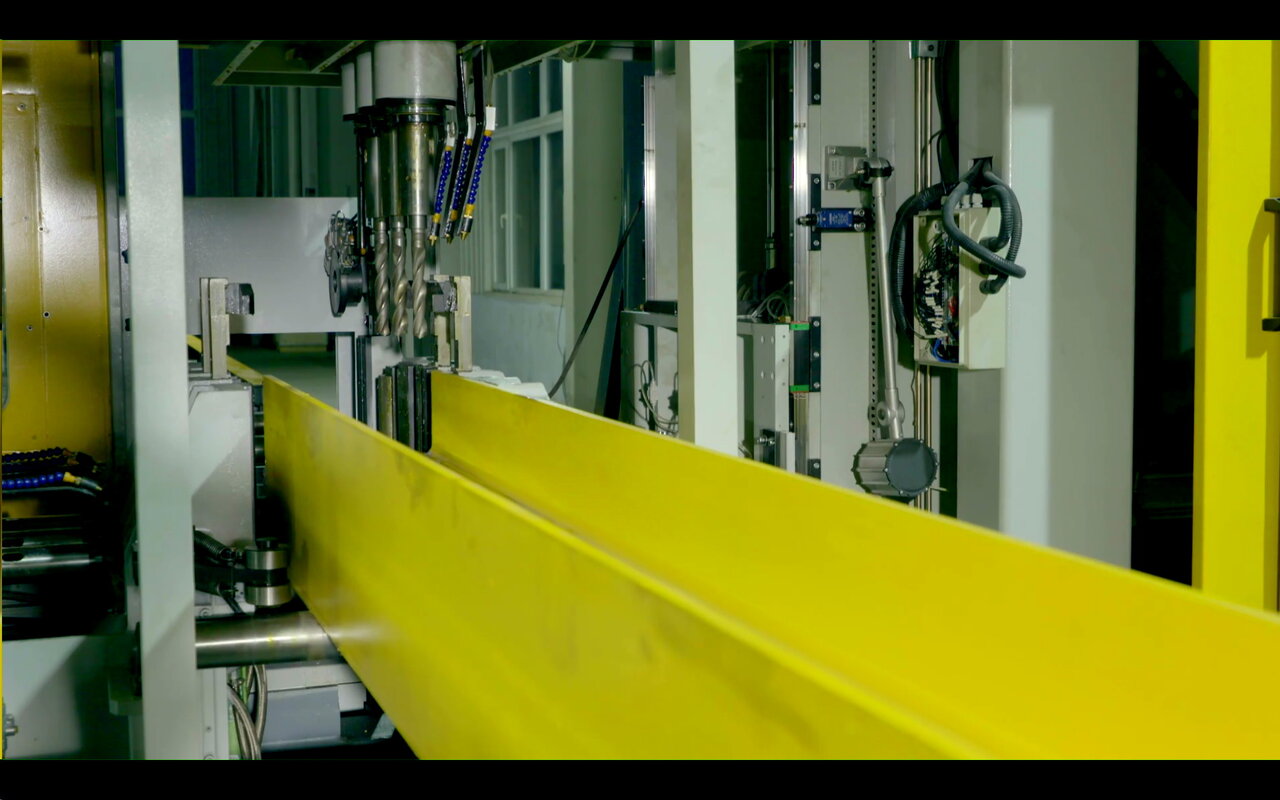

The Profidrill PDL-3D-PRO Drilling Lines have three independent spindles with each 3 tool positions (total 9 tools). They, have the capacity of drilling the profile from three sides independently at the same time.

Profidrill PDL-3D drilling lines for structural steel makers and fabricators

Profidrill PDL-3D Drilling lines for beam and structural steel, provide an affordable high quality solutions in manufacturing of steel construction, bridge construction, shipyards and various fields of construction sector.

Profidrill series have the drilling capacity of H, I, and U profiles or angles with 10-35 mm standard diameters or more.

PDL-3D-PRO – The automatic drilling line range

PDL automatic drilling lines are used for the drilling process of the IPE, HEA, HEB, UNP, U-Channel, Steel Angles, Square or Rectangular Tubes.

They have been developed with the purpose of increasing the production accuracy and efficiency of steel bars and profiles, which have been in continuous demand by the big steel construction companies.

The PDL-3D drilling line brings the needed automation in processing various shape bars by eliminating the preparatory work, positioning uncertainty thus significantly increasing the productivity and reducing the process time.

Add functionality to your production system

3 Sides drilling as standard

We deliver some of the best structural steel drilling machines on the market, and we can confidently offer some of the best prices on structural steel beam drill lines anywhere. It is not uncommon to save upwards of 20% or more over comparable competitors machines—all while maintaining machine quality, speed, and performance.

Feeding system with high precision gripper

| Specification | Unit | PDL-400-3D |

|---|---|---|

| Bar size (height x width) | ||

| Max. | mm | 400 x 400 |

| Min. | mm | 150 x 100 |

| Length, auto-feeding | mm | 1500 – 12000 |

| Bar max. weight | kg | 3000 |

| Max. thickness of profile | mm | 80 |

| Drilling diameter | ||

| Vertical drilling | mm | Ø12 – Ø33,5 |

| Horizontal drilling | mm | Ø12 - Ø30 |

| Total no. of spindle | 9 = 3 each side(top, left and right) | |

| Spindle speed range | rpm | 180 – 560 |

| Number of axes | 4 | |

| Feeding speed | mm/min | 20 – 300 |

| Feeding stroke | ||

| Vertical unit | mm | 240 |

| Left / right unit | mm | 240 (moving side) / 140 (fixed side) |

| Vertical spindle travel (beyond horizontal base level) | mm | 45 – 285 |

| Horizontal spindle travel (above vertical base level) | mm | 20 – 360 |

| Rated power | kW | 27 |

| Overall dimensions (Lxlxh) | mm | 4500 x 1800 x 2800 |

| Weight (machine – Machine + feed) | kg | 6500 - 12800 |

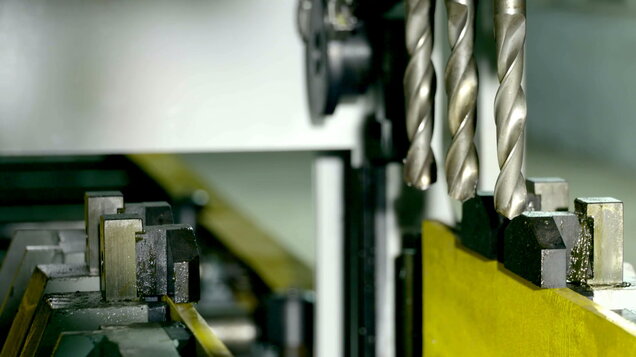

Automatic clamping system for material

Stable drilling with hydraulic fixed workpieces

Main Features:

- Ideal equipment for steel structure processing

- 4 (four) CNC controlled axes

- Simultaneous drilling on 3 sides

- All spindles adopt the CNC-controlled travel.

- Three different diameters of drill bits can be installed in each side to achieve high efficiency process = 9 tools available

- Direct conversion between CAD and CAM is available

- CNC lengthways measurement

- Spray cooling system of the drilling units

- In/ out feeding line 12m/4m standaard